Value analysis

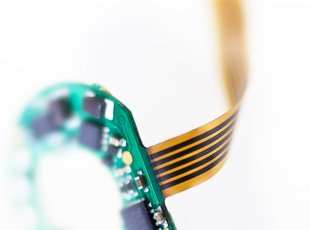

Lacon Engineering applies its value analysis methodology to achieve significant improvements and enhanced value for the objects processed from board layouts, modules and designs through to manufacturing processes. Value analysis is conducted on a per-project basis in small, interdisciplinary teams drawn from our development and production units.

The benchmark we apply here is a significant improvement in the effort/benefit ratio.

The potential for savings is usually high, since non-essential product functions (e.g.) can be corrected and new solutions discovered.

Goals for value analysis:

- Development and improvement of products and processes

- Time savings, achieved by taking a systematic and targeted approach to the issues at hand

- Staff motivation by involvement in problem-solving

- Quality improvements and cost savings of at least 10% – although typically 30–50%.