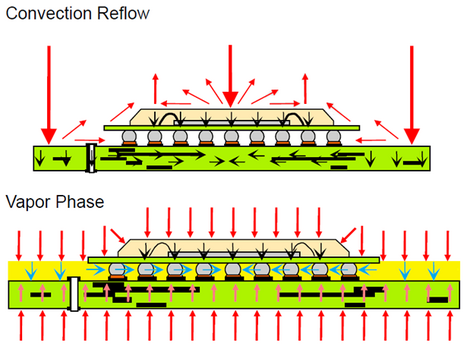

VapourPhase soldering is a condensation soldering method. The principle is based on using condensing vapour as a transferrer of heat. This principle is used in vapour phase soldering to transfer thermal energy onto electronic modules and to solder using the reflow method.

The standards set for the vapour medium are high:

- Corrosion must be excluded

- Electrically nonconductive

- Allow vapour temperatures without high pressure.

Liquids made of fluorocarbons are useful for this. Compared to normal convection soldering, heat can be transferred to the components to be soldered up to 10 times faster.

This makes vapour phase soldering an extremely protective component soldering method.

Higher heat transfer coefficient

- Smaller energy input, precise temperature control

- Outstandingly suitable for large components (e.g. IGBTs)

Gentle temperature rise immediately before reaching the solder’s melting temperature

- Prevention of tombstone effects

- Prevention of shrinkage cavity formation on large pads

Reliable prevention of temperature peaks

- No shortening of the life of sensitive components

- No delamination or popcorn formation on the printed board

- Simple module-specific modelling of the temperature profile

IBL – BLC609

Latest generation system:

- Measurement channels for recording board temperatures

- VP control for practical documentation and fine adjustment of the process

- RCS Rapid Cooling System (patented)

- Integrated fan for printed board cooling

- Low medium consumption due to 2-chamber design and medium recovery

- Automatic medium filtering

- Lead-free and lead-based soldering with only one medium with different boiling points

- Multilevel mode for easy switching between different soldering positions

- Soft Vapour Temperature Control (SVTC) for temperature-controlling profiles

ASSCON VP 56 and VP 3000

- Inline-capable VP 3000, operation as standalone

- Maximum flexibility, no time-consuming solder profile programming, no machine blockage

- Optimum temperature distribution over the circuit board and optimum solder result for large, energy-hungry components (e.g. inductors, transformers)

- Medium: Galden 230, boiling point 230 °C

- Minimum printed board stress