Hotmelt moulding

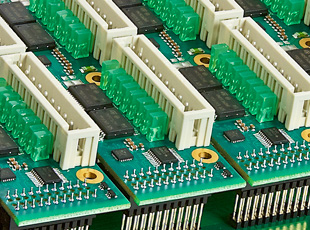

Hotmelt injection moulding technology for small and medium-sized cabling and connector batches:

- Significantly more cost-effective than other injection moulding options

- Low-pressure technology

- Aluminium moulds

- Direct application, even to sensitive components (boards, inductors, etc.)

The specifications can also be varied in terms of the softening point, operating temperature, bonding to the carrier material, viscosity, Shore A hardness, elongation after fracture and burning behaviour.

The hotmelt granulates we use are based on renewable raw materials that are solvent-free and can be worked using environmentally-friendly processes.

Typical applications for hotmelt moulding:

- Injection encapsulation of components (connectors)

- Strain relief by encapsulating the cable as it exits the connector

- Integration of electronics into cabling

- Logos and markings on the injection-moulded part

- Moderate costs, even for smaller batches

- Custom cable grommets

- Specialised cable kink protection