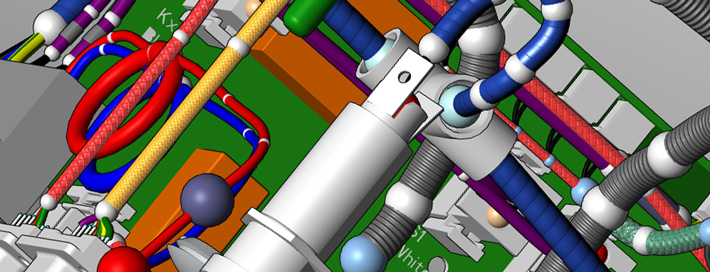

We design cables in space

EPLAN Harness proD as the most innovative 3D CAD system for cable designs.

What currently slows down your cable harness projects?

Do your service providers complain about unreliable document management, or the unwelcome additional work of parts list calculations, for far more complicated data integration than expected?

These are only a fraction of the innumerable disruptive factors that can occur, especially in highly complex cable harnesses, and often cause significant project delays.

As your EMS accelerator, we work with the EPLAN Harness proD design tool. This means we can achieve even more efficient design and documentation on a universal data basis.

Advantages at a glance:

- Clear project management of all documents and information of a cable harness project

- Extensive functions for the management of variants and options

- Automatic derivation of a 2D formboard drawing from the 3D cable harness

- User-defined material and parts lists, wiring plans as well as time, cost and weight calculations

- Individual formboard design in 2D, even without 3D data

- Import of 3D data; interfaces with standard MCAD systems and neutral CAD formats

- Individual definition of standard components such as connectors, cables, splices, etc.

- Open system; seamless integration into the product engineering process (PEP, PDM)

EPLAN Design

- Easy definition of cable and cable harness paths with intuitive “point-and-click” method in 3-dimensional space

- Easy import of wiring lists and connection information from EPLAN

- Fully-automatic routing of wires and cables on previously defined paths

- Continuously up-to-date values of bundle diameters and wire lengths

- Traceability (tracking) of all cable harness elements that belong together, such as wires, cable lugs, connectors, etc.

- Automatic placement of stop parts, plugs, etc.

- Test functions: Checking of minimum bending radii, cross-sections (including AWG) and cable harness conflicts as well as checking of bundle diameters and length restrictions

- 2D production drawings – from the 1:1 nailboard to handy service documents in the required scale

- Automatic production of delivery time and material estimating such as weight calculations as well as wiring and parts lists

- Derivation of control files for wiring and wire harness machines for optimum production integration