The quantity of electricity produced to operate all e-vehicles in Germany is not the problem. The load management is. In future, electric vehicles will be charged locally during work, shopping and not least at residential buildings. This is not possible without automatic and intelligent communication of vehicles, charging points and infeed.

Progress in eMobility is remarkable. In addition to higher charging capacities of the rechargeable batteries, loading points and communication behaviour of the controls are being advanced for the best possible use of tool lives. And: Anyone who wants to use or change over to an electric vehicle, quickly learns that it is not the trip to the petrol station that determines the range of a vehicle. On the contrary: Each stop can be used for charging.

"In future, we will charge our eCars everywhere: When shopping, parking, during work as well and not least at home. Local and easily accessible charging points will then be available for “short-term refuelling”, explained Thomas Klug, Managing Director of EAutoLader GmbH.

Klug does not accept the argument of a lack of power production to service the total quantity of all consumers. According to his calculations made in 2016, the net surplus electricity production of 124 terrawatt hours alone could be used to run around 45.1 million electric cars. If this astonishing figure is compared with all registered cars, at least 46.5 million (as of January 2018), it becomes clear why it is not the provision of the power but its distribution or correct organisation of the consumption charging that poses the greatest challenge.

How is the load distributed? The home time problem

In addition to the short intervals of standstill charging during the course of the day, the main load lies in the consumer’s charging behaviour after work, generally on work days between 17:00 and 20:00. During this time, load peaks increasingly occur in households, which connect all kinds of different loads to the power grid and use maximum power at the same time. Each housing complex with several residents, who drive home after work and want to fully charge their eCar, inevitably leads to a grid overload. In order to avoid darkness in the home, Klug advises simple load management in the housing facility.

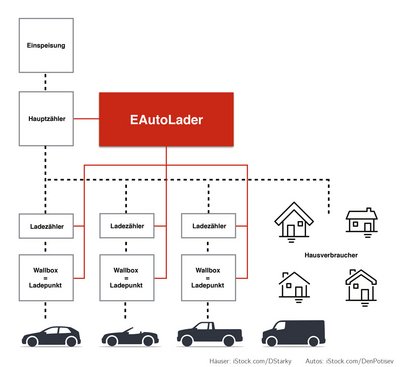

The concept is based on a simple control unit, which can be connected to different charging point systems regardless of their manufacturer. To prevent the house connection from being overloaded, the EAutoLader monitors and manages the EAutolader charging connections and house electricity.

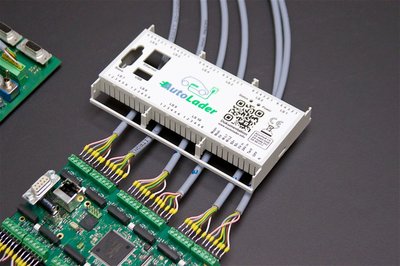

The management centre is only 16x9x3 cm (WxHxD) in size and is installed in the electrical distribution board with connections for power infeed and control boxes in the buildings. Up to ten charging points can be managed by each basic unit. Add-on modules (slaves) can be used to scale the system up to 120 charging points per infeed. Any electrician can carry out the installation quickly and easily and does not have to have complicated proprietary charging systems configured by specialists first.

"We manage the charging behaviour extremely easily”, is how Klug describes the load distribution: “The first person charges up to a capacity of around 80% first. They are then followed by all others. It is not a case of splitting the charging current, but of achieving the simplest (and fastest) distribution of the power to a consumer by switching on and off. The remaining 20% is assigned after this initial main charging process in the same order. However, whoever always wants to be first and not have to wait in the queue, can purchase priority treatment as a VIP.”

Professional development, as simple and as durable as possible

“We deliberately set ourselves from suppliers who tie their customers to them through enormous systems and sophisticated box builds and demand a lot of money each month for completely overpriced licence models for electronic frills. The EAutoLader is maintenance free, does not need the internet or updates. It manages the charging of vehicles absolutely reliably and simply, and costs a one-off charge of 980 euros plus. Finished.”, Klug says, declaring a war on commercial manufacturers. The focus of the application is therefore multi-dwelling housing and all facilities, which want to offer fundamentally simple load management and, for a minimum investment, prefer an independent maintenance free solution, from the trader around the corner to doctor’s practices through to employees who want to provide eMobility offers for their employees.

Development partner

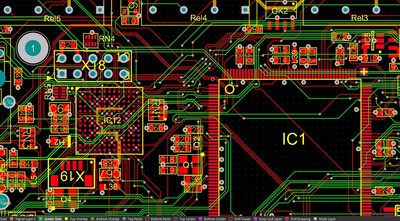

Lacon Embedded, the development forge of the Lacon Group in Karlsfeld near Munich, is responsible for the overall project.

- Component selection, software programming, quality assurance and box build are carried out on site.

- The concept and layout of the printed board are focused on robustness and the easiest possible implementation.

- The routes are short, because all boards are assembled, tested and processed into the end product next door in the main Lacon factory.

- The product has been tested and certified for electromagnetic compatibility in an accredited laboratory.

- The routes are short, because all boards are assembled, tested and processed into the end product next door in the main Lacon factory.

- The product has been tested and certified for electromagnetic compatibility in an accredited laboratory.

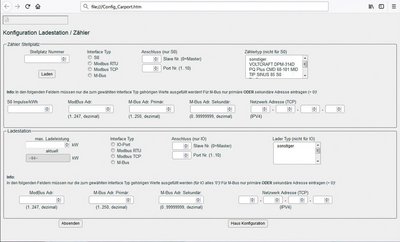

Project developer Martin Räuschl explains what is important: “Simple parameter setting via a local laptop with a browser and cross-manufacturer design are the core requirements, our path was therefore already defined. We concentrated first on the right controller, so that the whole IP stack does not have to be programmed manually. With the DHCP-compatible ethernet interface, M-bus and modbus, we cover all connection options the market demands. The power adapter is external, so that no load passes via the board and no heat develops in the device. The whole unit is naturally much less expensive if I don’t need fans or a transformer. There are no security problems because we don’t dial into the internet. Anyone who wants to hack the EAutoLader has to pluck it out of the garage...“

The device closes the market gap between expensive proprietary models, for which the cost of the basic unit starts with fixed costs of 1,200 euros and some of which demand monthly licence fees and the makeshift solutions from the garage, which are detached from security and quality aspects. The EAutoLader values top quality with maintenance free operation.

“In reality, the test phase is the decisive development step.” Räuschl dryly added: “We had to develop a test device that can simulate all charging points with all kinds of different requirements and causes the greatest possible difficulties for the EAutoLader.” The envisaged test environment simulates the simultaneous operation of 10 charging points.

Only after the EAutoLader control has passed through all load tests successfully can it be used in the field.

Parameter setting on the html interface has been kept as simple as possible. This is where the basic information on the bus and meter types, addressing and maximum charging capacity is entered.

Why is the socket in the wall not the solution?

It is often argued that normal charging overnight does not need load management. This forgets that nowadays, all eMobility solutions are less concerned about “the power” and are more focused on communication between the devices. Each vehicle exchanges data with the charging equipment, based on the power input, charging voltage and capacity, charging readiness and release, possible error messages and other parameters have to be exchanged. Klug chuckled: “The most important factor, by the way, is that a vehicle is really a vehicle, the controls speak to each other intensively. No questions: Security aspects must always come first and exclude individual makeshift solutions.“

In addition, a standard socket provides an output of 2.7 kW only. It takes around 7 hours to charge 100 km capacity with it, a power current infeed with 16 A per phase provide 11 kW, so that a shopping trip or a visit to the doctors is “rewarded” with 30 km in 30 min.

Summarising

The EAutoLader offers robust, simple load management, which has maximum reliability and is durable, and can handle almost all standard connections on the market across all manufacturers. The device is easy to install and can be configured by anyone, it is scalable and cost-effective. There are no hidden costs or licence models. The target group are multi-dwelling housing, building management companies and providers of charging points while customers shop or undertake sports and leisure activities. It also addresses companies that want to offer their employees charging of their vehicles during working hours.